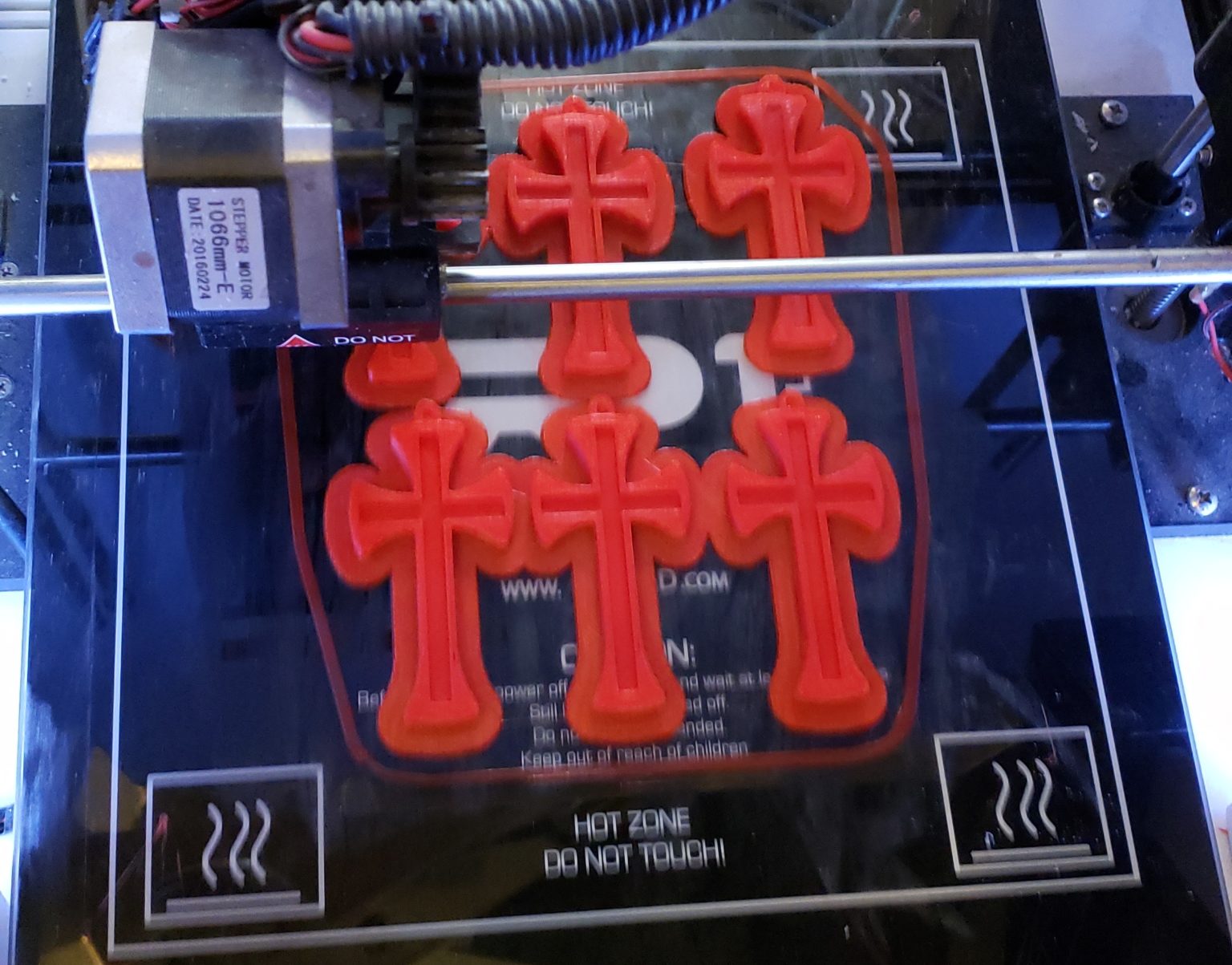

3D CAD Design

We use the newest 3D CAD design software to create part and assembly models before milling your prototype. Giving you a visual representation of your future prototype.

The newest 3D CAD design software offers unparalleled capabilities for creating detailed part and assembly models, setting a strong foundation before milling your prototype. With advanced modeling tools, you can precisely define the geometry, tolerances, and features of each component. These tools also enable you to simulate the mechanical behavior of the parts, ensuring that your design performs as intended under various conditions. By refining the design virtually, you save time and materials, avoiding potential errors during the physical milling process.

Modern 3D CAD Software

One of the most significant advantages of using modern 3D CAD software is the ability to work seamlessly with assemblies. The software allows you to visualize how individual parts interact within a larger system, helping identify potential interference or misalignment issues before manufacturing. Additionally, you can apply motion studies and stress analyses to optimize the functionality of your design. These capabilities ensure that your prototype is not only accurate but also optimized for real-world applications, ultimately reducing the need for iterative physical testing.

Finalizing the Design in CAD

After finalizing the design in CAD, the software enables direct integration with CAM (Computer-Aided Manufacturing) systems, streamlining the transition from design to milling. The detailed CAD model serves as the foundation for generating precise toolpaths and machining instructions. This integration ensures that the milling process is efficient and accurate, reducing material waste and production time. By leveraging the latest 3D CAD software, you can confidently move from concept to prototype, ensuring a high-quality output that meets your design specifications.