In today’s fast-paced world, innovation is the key to staying ahead of the competition. Whether you’re an entrepreneur with a groundbreaking idea or an established business looking to refine your product, prototyping plays a pivotal role in turning concepts into tangible results. At the heart of this process is our use of cutting-edge 3D CAD (Computer-Aided Design) software to create detailed part and assembly models before milling your prototype.

The Power of 3D CAD Design

Gone are the days of relying solely on rough sketches and manual drafting. Modern 3D CAD design software revolutionizes the way prototypes are developed by offering unparalleled precision and flexibility. Here’s how we leverage this technology to deliver exceptional results:

- Visualizing Complex Designs: With 3D CAD software, we create highly detailed digital representations of your parts and assemblies. This allows us to identify potential design challenges early in the process, saving time and resources.

- Customization and Iteration: Whether it’s a single component or a complex assembly, the software enables us to make quick adjustments and test different variations to ensure optimal functionality and aesthetics.

- Accurate Measurements: Precision is non-negotiable when it comes to prototyping. 3D CAD tools ensure that every dimension and specification is accounted for, reducing the margin for error during the milling process.

- Enhanced Collaboration: The digital models we create can be shared with clients, engineers, and other stakeholders. This transparency fosters collaboration, ensuring everyone is aligned before moving to the production stage.

“I must explain to you how all this mistake idea denouncing pleasure & praising pain was born and I will give you a complete account of the system, and expound the actual teachings of the great explorer of the truth, the master-builder of human happiness.”

Emma Smithson

Bridging the Gap Between Design and Manufacturing

Once the 3D CAD model is perfected, the next step is bringing it to life through milling. Here’s where the synergy between advanced software and cutting-edge machinery truly shines:

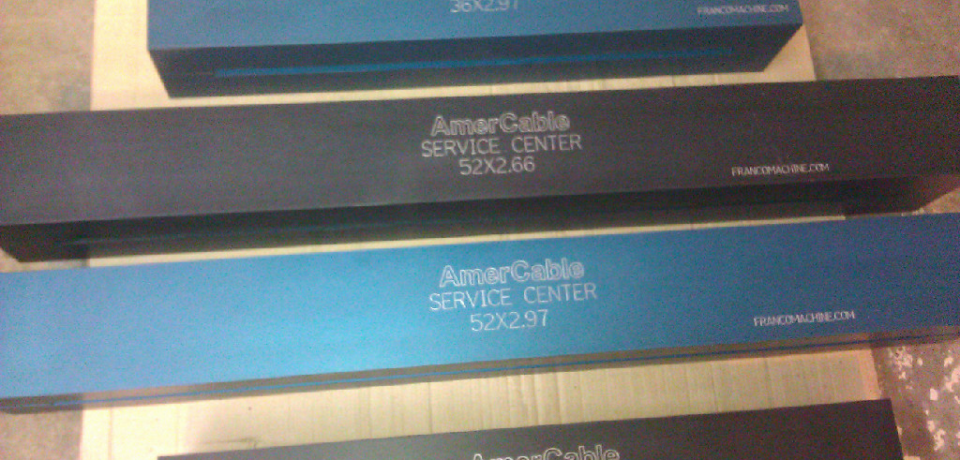

- Seamless Transition: The precise digital models generated by our 3D CAD software serve as the blueprint for our milling machines. This eliminates guesswork and ensures that the physical prototype matches the virtual design.

- Material Versatility: Whether you need metal, plastic, or composite materials, our milling process is equipped to handle a wide range of options to suit your project’s requirements.

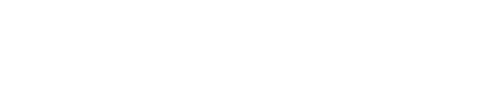

- Rapid Prototyping: By combining the speed of CAD design iterations with the efficiency of milling, we can quickly produce prototypes, allowing you to test and refine your product without delay.

- Cost-Effectiveness: Detecting and addressing design flaws in the digital stage prevents costly mistakes during production, ensuring you get the best value for your investment.

Why Choose Us for Your Prototyping Needs?

At our facility, we’re committed to delivering excellence at every step of the prototyping journey. Our team of skilled designers and engineers utilizes the latest 3D CAD design software and state-of-the-art milling machines to turn your ideas into reality. Whether it’s a single prototype or a complex assembly, we’re here to help you bring your vision to life with precision and efficiency.

Ready to take your product from concept to creation? Contact us today to learn more about how our advanced 3D CAD design and milling services can transform your ideas into tangible success.

Crafting Hardcore Parts to Impress You and Your Investors

- admin

- December 17, 2024